At the end of 2021, the French Armaments Directorate (French: Direction Générale de l'Armement; DGA ) carried out a major test for the development of the next fighter engine of the Future Combat Air System (FCAS) (French: Système de combat aérien du futur; SCAF) As part of the DGA-led Turenne defense technology project, a prototype derived from the Rafale fighter jet engine was tested on the test bench. A unique, highly technical test, which required 5 years of preparation in order to develop the technologies useful for the future engine of the FCAS combat aircraft.

Follow Air Recognition on Google News at this link

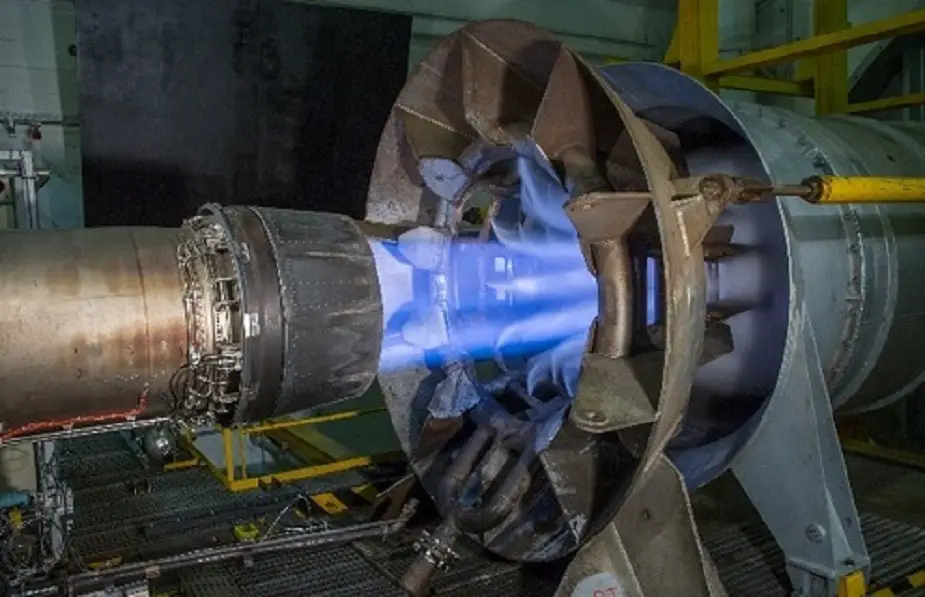

Engine on the test bench (Picture source: DGA)

Engine on the test bench (Picture source: DGA)

Initiated in 2015 by the DGA and entrusted to Safran, the Turenne program consists of two phases:

The 1st phase lasted 5 years, under the supervision of DGA Project Engineering on the Balard site in Paris, to create, test digitally, and produce an innovative concept of a turbine using modern processes: scalable digital model, 3D digital simulations, digital design of new metal alloys, prototyping in additive manufacturing. This revolutionary turbine has also been the subject of international patent applications ... with engineers from the DGA as co-inventors!

The 2nd phase, started in 2019, allows the prototype to be tested in the field using the Thermocolor technique, with the objective of comparing the thermal mapping obtained in reality with the data from the simulations carried out digitally in phase 1.

This test is specific by the technique used, called Thermocolor, which requires heat-sensitive paint; applied to the blades of the engine's high pressure turbine blades, it allows the temperature to be measured by means of a color change. This paint is very fragile: by its composition, it can only undergo a single thermal stress. Then it loses its properties. Therefore, this type of test is very rare; the most recent at DGA Propellants tests dates back to 2010.

The turbine developed as part of the Turenne project (Picture source: DGA)

The turbine developed as part of the Turenne project (Picture source: DGA)

A long series of tests is to come in the centers of the DGA. As part of a roadmap steered by the architects of the DGA Project Engineering center, this Thermocolor test marks a new phase in the maturation of technologies critical for the future of combat aviation. Once the results have been analyzed, a so-called "endurance" test will be carried out for several months, again at DGA Propellants Tests. The objective is to impose accelerated aging on these new engine turbine blades, to verify their lifespan and their ability to guarantee a high level of operational performance over long periods of time.

At the same time, the DGA Techniques aéronautiques test and expertise center in Balma , near Toulouse (France), is working with Safran on the development of new ceramic materials resistant to high temperatures. In the coming years, it will also carry out tests on new generation metallic materials which will allow their resistance to be characterized.

Each of these advancements is a unique and necessary piece of a puzzle of technological innovation. Combined in a latest generation engine, they will achieve the level of performance expected from the FCAS program.